The Ultimate Buyer’s Guide to Acoustic Fencing and Sound Walls

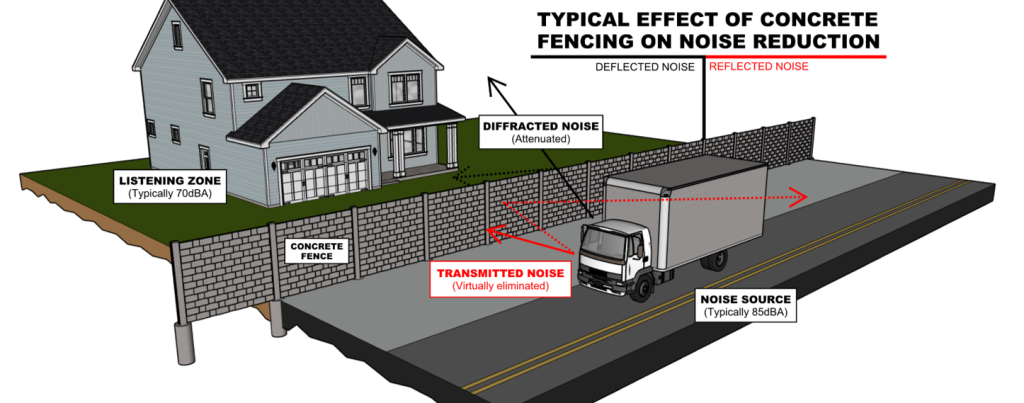

Whether you’re trying to block out the hum of nearby traffic or mitigate the disruption of industrial machinery, acoustic fences – also referred to as sound walls or sound barriers – can make a world of difference. The selection process can be tricky as you weigh performance, cost, and aesthetics to the many options out there. So, let’s start the conversation with arguably the most important factor with it comes to sound walls – performance.

In this guide, we explore the main types of acoustic fencing – timber, metal, PVC/composite, and concrete – comparing their pros, cons, average STC ratings, and best applications. And while each has its place, we’ll let you in on the expert combination to help achieve both effective sound blockage and budget consciousness using precast concrete.

What Is an STC Rating?

STC (Sound Transmission Class) is a standardized way to measure how well a building material attenuates airborne sound. The higher the STC, the better the sound barrier is at blocking noise. STC is a good way to understand a product’s capability of reducing noise disruption.

Here’s a quick rule of thumb:

- STC 20–30: Minimal sound reduction (you can hear speech clearly through it)

- STC 30–40: Good sound reduction (raised voices can be heard faintly)

- STC 40-50: Excellent – most typical noises are significantly reduced or inaudible

1. Timber Acoustic Fences

Average STC Rating: 25–30

- Pros: Natural look, easy to install, decent acoustic performance when sealed properly

- Cons: Requires maintenance, not ideal for long-term exposure to harsh weather, limited sound reduction (mostly absorbs mid-range frequencies)

Best for: Residential or suburban light use where aesthetics matter more than heavy-duty noise control.

2. Metal Acoustic Panels (Steel or Aluminum)

Average STC Rating: 30–40, depending on core insulation

- Pros: Durable and relatively lightweight, often used with absorptive layers, scalable

- Cons: Reflective unless treated and can become very hot to the touch, may transmit vibrations, vulnerable to denting or corrosion over time

Best for: Factories, commercial zones, or utility areas needing durable noise control solutions.

3. PVC and Composite Barriers

Average STC Rating: 25–35

- Pros: Weather-resistant, lightweight, and easy to install.

- Cons: Less effective at blocking low-frequency sounds like engines or traffic, can become brittle in cold climates, requires core additives that can elevate costs, can be reflective

Best for: Residential or light commercial properties looking for an attractive barrier with modest noise control.

4. Concrete Sound Walls (specifically precast)

Average STC Rating: 40-50

- Pros: Exceptional sound attenuation, extremely durable, low maintenance, easy to scale up for robust needs

- Cons: Heavier, more expensive to transport

Best for: Commercial and industrial properties, utility and high security facilities, and high-end residential where long-term performance is key.

Why Precast Concrete Quietly Leads the Pack

When maximum sound separation is the goal, concrete barriers consistently outperform other options, especially in harsh or demanding environments. As such, many would assume that concrete also comes with the biggest price tag, however, precast concrete sound walls can be surprisingly affordable due to manufacturing efficiency, easier transportation, and low-complexity installations. Precast concrete acoustic fences, like Dura-Crete Walls, can easily solve noise pollution problems without being exorbitantly expensive and can scale up to 30 feet tall making is an effective solution for a wide variety of applications.

Each acoustic fence material has its strengths, and your choice should reflect the site conditions, noise levels, and aesthetic goals. But if long-term durability, minimal upkeep, and maximum sound reduction are priorities — precast concrete stands out as the quiet, confident choice.

Need help mitigating noise disruption at your facility? Contact our team at info@duracretewalls.com or 586-759-4286 to discuss your project goals and find the solution that fits — acoustically and financially.